Becker T-Ball Valves

Becker

Product

/Pipeline Control Valves

Features and benefits

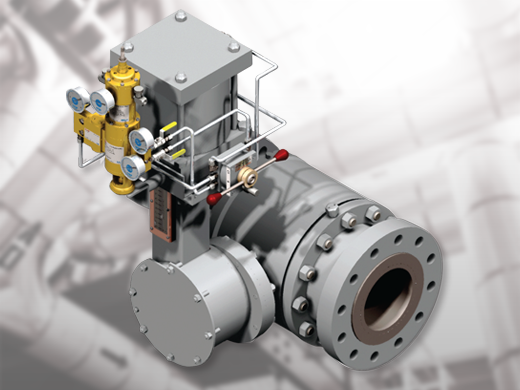

Becker T-Ball Control Valves for Natural Gas Applications

Natural gas systems are in the quest for maximum capacity and operational efficiency. As a result of trying to meet increasing market demands, many regulator station designs are exceeding the performance envelope of other control valve manufacturers. When it comes to high demand natural gas regulation requirements, the Becker T-Ball Control Valve series offers a series of valves that can help you to optimize your system’s performance.

Baker Hughes’ solution can take on demanding applications that require aggressive noise attenuation, high pressure differentials, large mass flow volumes and extreme precision. In addition, the Becker T-Ball can handle a variety of media from sweet natural gas to multiphase service to corrosive sour gas.

The Becker T-Ball benefits include:

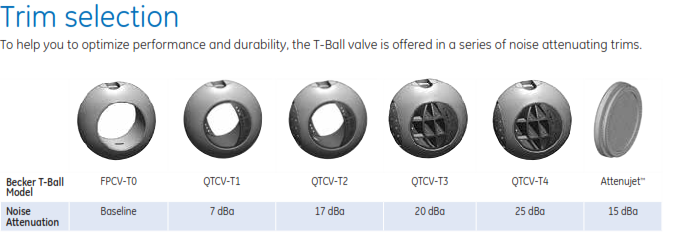

Optimized trim selection:

The T-Ball valve can be easily customized by Baker Hughes’s experienced engineers to suit your specific application requirements. Available in a full range of trim designs (FPCV-T0, QTCV-T1, QTCV-T2, QTCV-T3 and QTCV-T4), this valve can be configured to meet your precise flow rate and noise attenuation specifications. For example, applications that require high mass flow rates without the need for noise attenuation are well suited to the conventional full port design of the FPCV-T0 mode. Applications that require high-pressure differential and aggressive noise attention are ideal for the QTCV-T4 model. In addition, Baker Hughes offers optional construction materials, including exotic alloys and hardened overlays, that can increase service life and performance in rugged applications

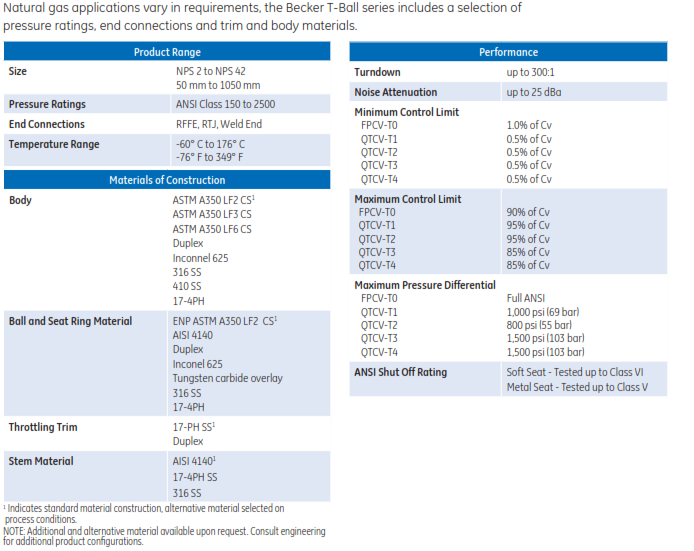

Product Range:

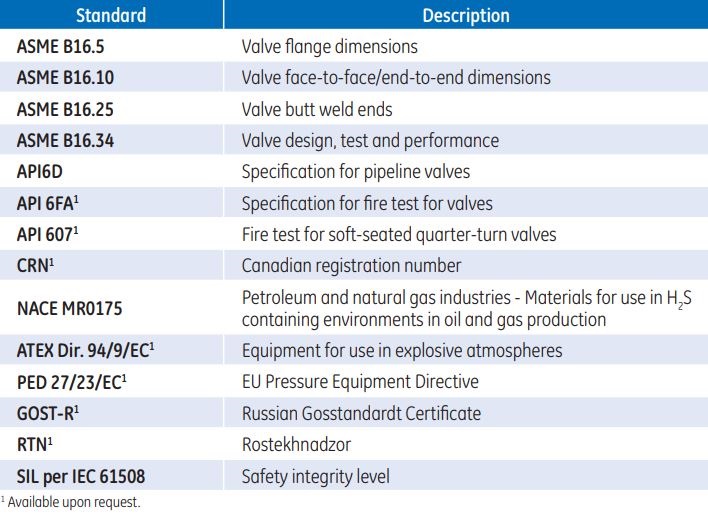

Our products are engineered, built and tested in accordance with the industry’s international standards to enhance the quality of our products.

Applicable Industries

Key Applications:

Above and Underground Storage, Conventional adn Unconventional Production, Compressor Stations, Gas Transmission, Gas Power Plant Feed, Natural Gas distribution, Petrochemical feed