Product

/Severe Service Control Valves

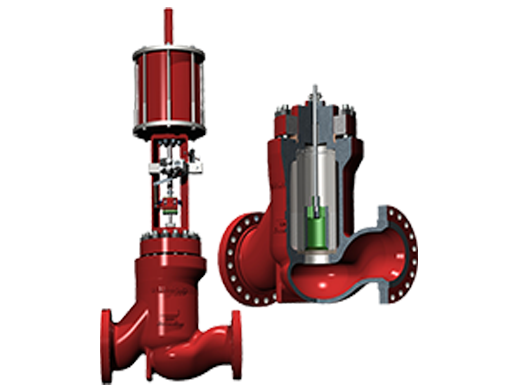

Masoneilan 74000 Series Heavy Oil Process Valve

Specification

- Size: 2” x 3” through 12” x 14” (50 x 80 mm through 300 x 350 mm)

- Ratings and Connections : flanged or hub: ANSI 150 - 2500

- Body Materials :347 stainless steel; other alloys on request

- Actuators :model 87/88 multi-spring-opposed diaphragm; model 51/52/53 piston cylinder

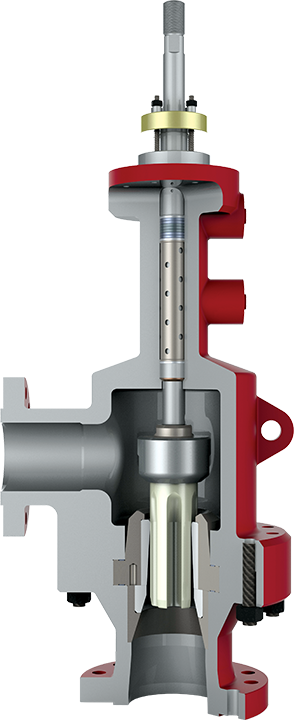

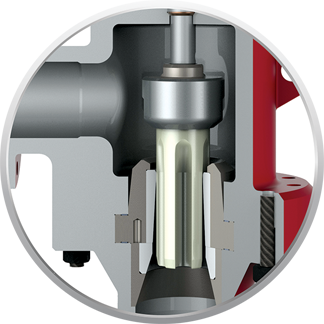

- Trim :Body-retained seat ring with sacrificial venturi for body protection; fluted or bull-nosed plug with continuous heavy shaft guiding; trim components available in high alloy base with erosion resistant coating or ceramic; purge connection for flushing upper body cavity

- Inherent Characteristics :linear

Description

The base level 74000 series valve is characterized by a single stage trim, packaged in an angle style valve body, and having relatively simple flow geometry, for both the valve body and trim. This simplicity of flow path has proven successful in targeted heavy oil applications where high-velocity erosive jets are destroying more complex valve trims. This product has been uniquely successful in tough refining applications where entrained solids are the primary concern, and where other conventional severe service trims have failed catastrophically. The 74000 has industry-wide endorsements for success under the toughest of conditions, and is frequently specified by name with experienced users. When seeking products that are differentiated in the market, the 74000 stands out as unique in both design and performance.

Refining solutions

With over 35 years of installation history, the Masoneilan 74000 series valves serve a unique role in advanced oil refining operations. One leading-edge refining process is known as Residual Hydrocracking. Positioned downstream of the vacuum unit, this process converts “bottom-of-the-barrel” residuals through a reactor to produce high value mid-distillates such as diesel. This fluid is laden with point-of-origin contaminants and particulate matter, and when combined with abrasive catalysts can destroy conventional control valves in a matter of days, or even worse. This is where the 74000 shines.

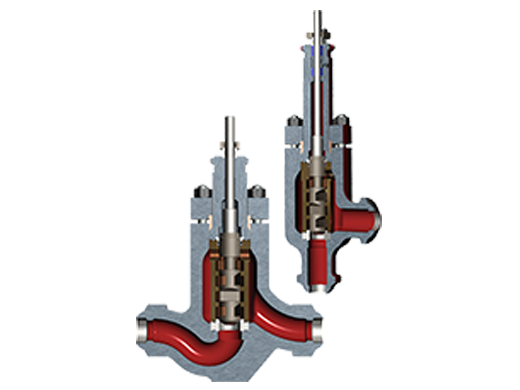

The 74000 series is the next tier in severe service that takes over in extremely erosive applications where traditional high-pressure reduction, severe service refining products like the Masoneilan LincolnLog and 77003 series become limited due to the erosive flow characteristic.

Unique Severe Service Design

Residual Hydrocracking introduces process attributes that require valve features that can hold up under a combined load of pressure and temperature with entrained solids yielding severe erosion. Some of these valve applications are so erosive that conventional trim staging is not effective, and is in-fact self-limiting.

The 74000 design counters this with ample transition areas and flow path management to reduce body impingement

High Pressure DropThese can be so severe and at such high velocity that the confined spaces and convoluted geometry of multi-staging can be ineffective, even destructive as the high velocity flow impinges on trim and body surfaces. The 74000 employs a rugged single-stage design with minimal internal impingement, leading to simple flow lines and managed velocity

High Velocity Erosive FlowThe 74000 employs a unique tungsten carbide surface treatment on the plug and seat ring and includes a sacrificial ceramic venturi tube below the seat where velocity is the highest and most destructive.

Process OutgassingTo deal with process fluid changing state from liquid to gas as a result of the severe pressure drop, the 74000 has an integral expanded outlet to manage downstream velocity. Bear in mind that the solids are present in the valve outlet flow, and with increased outlet velocity due to outgassing, severe erosion is present and destructive.

Longer Intervals Between MaintenanceRefinery units typically target turnaround intervals in the range of around 3 years. In many cases, inferior control valves are driving dramatically shorter intervals measured in months rather than years. The 74000 has proven considerably longer cycles, in many cases matching targets of 3+ years, with some applications even doubling those intervals.

Applicable Industrie

Refining

Key Applications :

Residual Hydrocracking, Heavy Oil Letdown, 2-phase erosive service.