Product

/Severe Service Control Valves

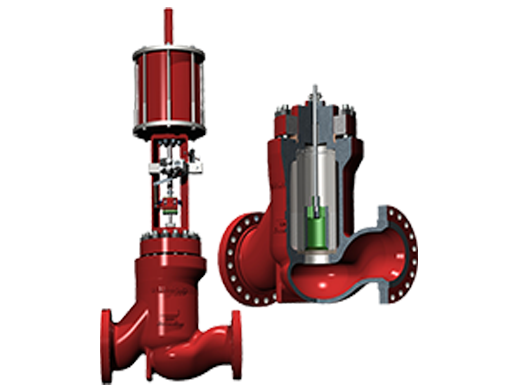

Masoneilan-84000-Series-SteamForm-Steam-Conditioning

Specification

- Size: Trim Sizes: 3” through 24” (80 through 600 mm); Pipe Sizes: 3” through 48” (80 through 1200 mm)

- Ratings and Connections : flanged: ANSI 150 - 2500 UNI-DIN 10 - 400; welded: BW

- Body Materials :carbon steel; chrome-moly

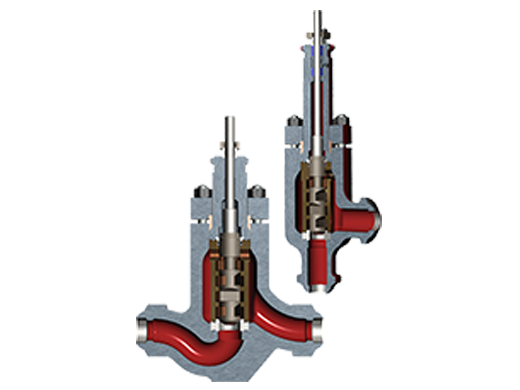

- Actuators :model 87/88 multi-spring diaphragm; model 37/38 spring diaphragm; cylinder

- Trim :single or double stage Lo-dB with optional diffuser and V-LOG energy management trim; thermally compensated high temperature trim options

- Inherent Characteristics :linear or equal percentage

Description

The Masoneilan line of steam conditioning valves offers a wide range of features, including low noise trim and a patented water injection system, for applications that require both pressure and temperature reduction in an integrated package. The SteamForm* product line combines more than 125 years of pressure control expertise with the latest in desuperheating technology to offer a highly efficient steam conditioning solution.

Benefits of the 84000 Series SteamForm™ Steam Conditioning Valve include:The Masoneilan 84000 SteamForm valve is a superior choice for steam conditioning applications requiring integrated pressure and temperature reduction such as:

Applicable Industrie

Power Generation, Refining, Petrochemicals, Pulp/Paper.

Key Applications :

Steam Turbine Bypass, Auxiliary Steam Conditioning, Process Steam Letdown, Desuperheating.