Product

/Rotary Control Valves

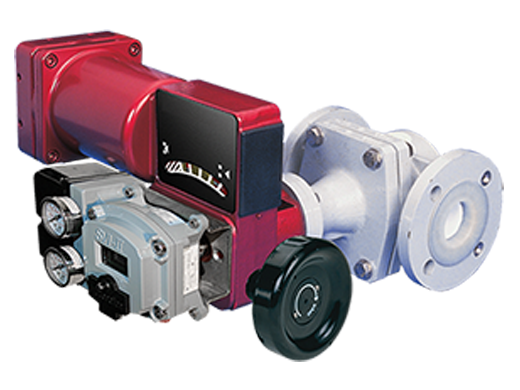

Masoneilan 35002 Series Camflex™ Rotary Control Valve

Description:

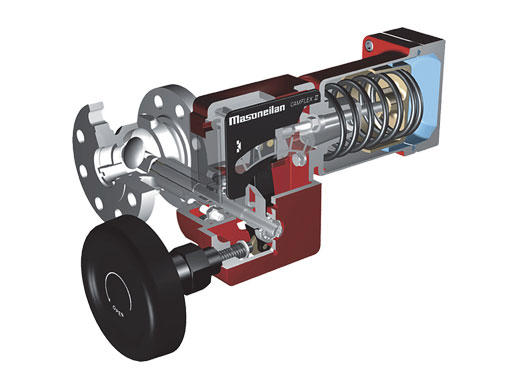

When the original Camflex was introduced in 1968 it created a revolutionary new category of control valves -the Rotary Globe. This new type of valve converged the best control features of a conventional globe valve with a rotary action to produce a valve capable of replacing at least 80% of the control valves in use at that time. Many improvements and enhancements have been made since that time, with over 1 million Camflex valves installed in a wide range of process control applications. Everything from the most basic water applications up to severely erosive services that would tear other valves apart. The Masoneilan Camflex valve is designed first and foremost to be an excellent control valve and has proven to truly be a Universal Rotary Globe control valve.

Specification

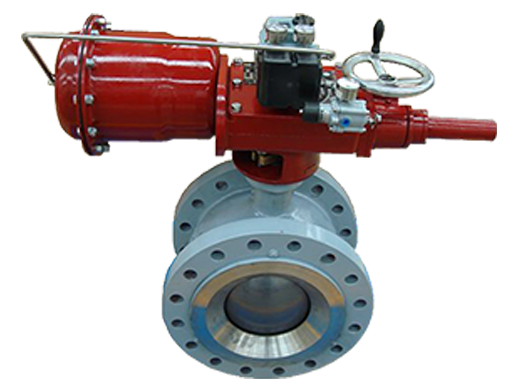

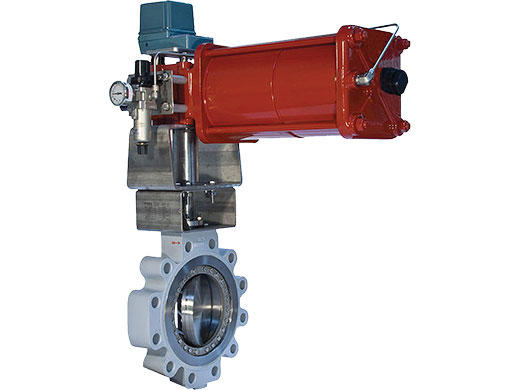

- Size: 1" through 16" (25 through 400 mm)

- Ratings and Connections: Flanged: ANSI 150 – 600

Flangeless: ANSI 150 – 600 UNI-DIN 10 – 100

Screwed: NPT (1" through 2") - Body Materials:Carbon steel Stainless steel High nickel alloy

- Actuator:Model 35 spring diaphragm

Model 70 Series cylinder - Trim :Eccentric rotary plug

- Inherent Characteristics :Linear

CAM-flex

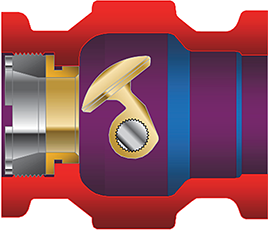

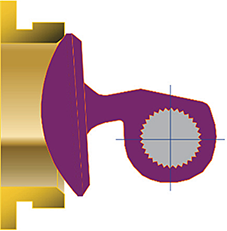

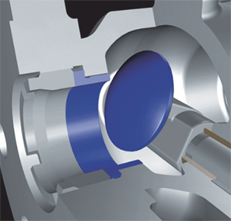

The heart of the Camflex valve is its eccentric plug. The eccentrically rotating, double offset plug CAM’s into and out of the seat. This camming action eliminates friction throughout its rotation since the plug moves away from the seat as it opens, unlike other rotary valve types. This ensures precise control at all openings.

CAMP-flex

The plug is offset such that the trailing edge of the plug face will contact the seat ring first when closing. Additional plug rotation causes the plug arms to flex slightly, moving the plug face into full contact with the seat. This flexing action ensures tight long-term seating with smooth seating/unseating action.

Wide Application Range

The standard construction of the Masoneilan Camflex valve includes features that are either optional or simply not available in competing valves.

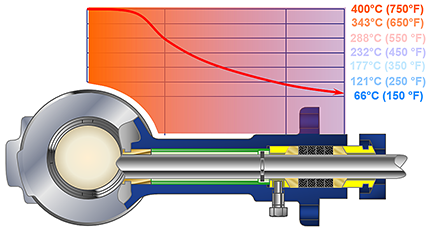

Integral Extension Bonnet

The integrally cast extension bonnet provides effective radiation of heat in high temperature applications to allow the use of low-friction TFE packing materials across the full rated service temperatures of -196˚C to 400˚C (-320˚F to 750˚F). Graphite based packing is available as an option for fire-safe applications.

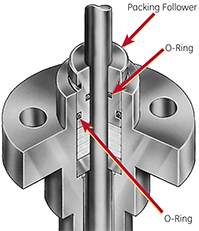

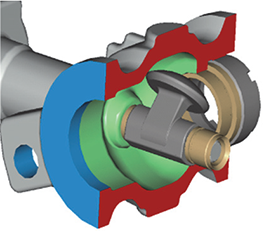

Standard Low-Emissions Packing

One of the biggest sources of fugitive emissions in plants and pipelines are valves, specifically, emissions leakage from the packing box and sealing gaskets. With an integral bonnet design, the Camflex completely eliminates emissions from the bonnet joint, a huge differentiated benefit over globe valves of similar pressure class. The Camflex further stands out minimizing packing leakage as every valve produced today comes standard with the EF Seal, low-emissions packing system. This simple double O-Ring sealed packing system satisfies FCI 91-1 (EPA) requirements. In addition, the Optional Low-E packing system has been independently certified to the ISO 15848-1 Class A requirements with both Helium and Methane gas tests. Measured results are more than 25x tighter than the ‹ 100 ppm requirement. This system also satisfies the U.S. EPA Certified Low Leak Technology (CLLT) requirements.

Linear Flow Characteristic with Higher Turndown

Camflex’s linear flow characteristic provides a slight modification as the plug approaches the seat. As the plug cams into the seat, the rate of change in flow is reduced gradually until the plug contacts the seat. This provides a Cv ratio of 100:1 for stable operation over a wider range in flow. Most traditional globe style control valves offer 50:1 maximum.

Designed to Resist Erosion

Hardfaced or solid Stellite plug is standard in every Camflex with optional seat rings and retainers available for erosive applications. Guide bushings are located outside flowstream to prevent impingement of damaging debris on critical guiding surfaces

These features help provide extended service life in harsh services.

Smaller, Lighter, Easy to Handle

The Masoneilan Camflex II is also much easier to install and maintain thanks to its flexible body options. Available in Threaded, Flangeless or Flanged ends to match pipe connection requirements. The flanged construction is also offered in the Camflex GR configuration, which matches the face to face dimension of most standard globe valves allowing simplified replacement of existing valves.

Regardless of end connections option, Camflex valves are much smaller and lighter than globe valve products

– typically half the size and half the weight.

Minimized Parts

The Masoneilan Camflex II incorporated product stewardship from initial concept. Not only does it eliminate a bonnet gasket in the standard design, it only requires one plug across a single valve line size. The design features different seat rings to achieve a variety of flow conditions without the hassle of changing a plug, cage and/or stem size. This will help minimize the required inventory on the shelf and share a common part among other Camflex installations of the same body size.

Low-Noise Trim Option

An optional patented differential velocity device (DVD) separates compressible flow streams into a high velocity core and a low velocity envelope flow stream. This differential velocity concept is similar to that used in commercial jet engines and provides up to 18 dBA noise attenuation.

Applicable Industries

Power Generation, Refining, Petrochemicals, Midstream Oil and Gas, Upstream Oil and Gas, Pulp/Paper.

Key Applications :Condenser, Cooling Tower, Reactor Building, Turbine Building, Reactor Facility Grounds and BOP, Gas Turbine, Balance Of Plant, Distillation, Hydroprocessing, Reforming, Cracking, Secondary, Blending, Quenching and Fractioning, Charge Gas Compression, Seperation, Pipeline Integrity, Operations, Dehydration, Refrigeration, Liquifaction, Loading/Shipping, Regasification, Auxillary, Dehydration/Treating, Compression.