Heat Exchanger

This allows the temperature range for the 3900 POSRV with

metal seats to be extended to -320°F to 650°F (-195.5°C to

343.3°C). Not available above 3750 Psig (258.5 barg). When the

heat exchanger is selected, the POSRV shall be piped so that the

media enters the heat exchanger first to condition the media’s

temperature. Option(s) such as line filter, canister filter, 5-way

manifold valve, pressure differential switch, pressure spike

snubber, etc. shall be piped downstream of the heat exchanger.

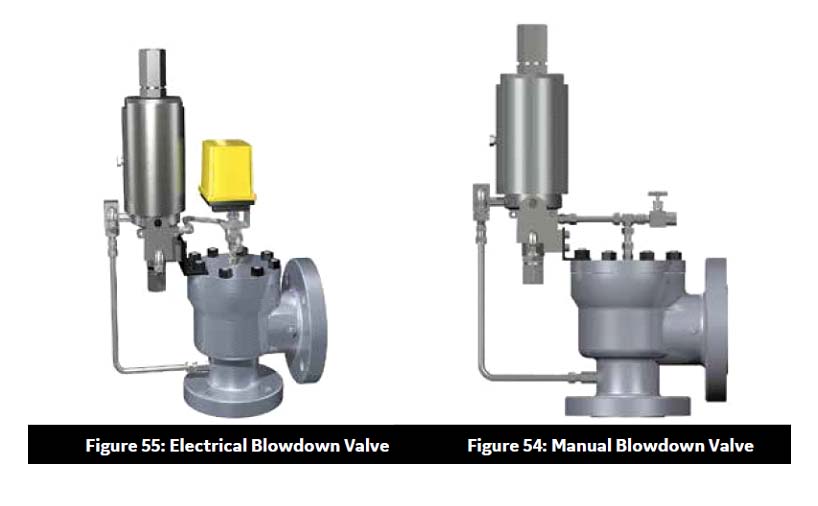

Manual, Electrical, or Pneumatic Blowdown Valve

An optional manual blowdown valve is available for relieving

the pilot operated safety relief valve. Consult factory for

applications requiring a pneumatic or electrical solenoid

blowdown valve which may be connected to a distant

location, such as an operator station, for remote actuation.

The blowdown valve is ported directly to the main dome area,

so that the media in the dome is vented when the blowdown

valve is actuated, thus allowing the main valve to open.

Pressure Spike Snubber

BHGE recommends the use of a pressure spike snubber

for all applications which may have high frequency pressure

spikes. The pressure spike snubber is designed to

dampen the pressure spikes which could cause unnecessary

parts wear or premature valve opening.

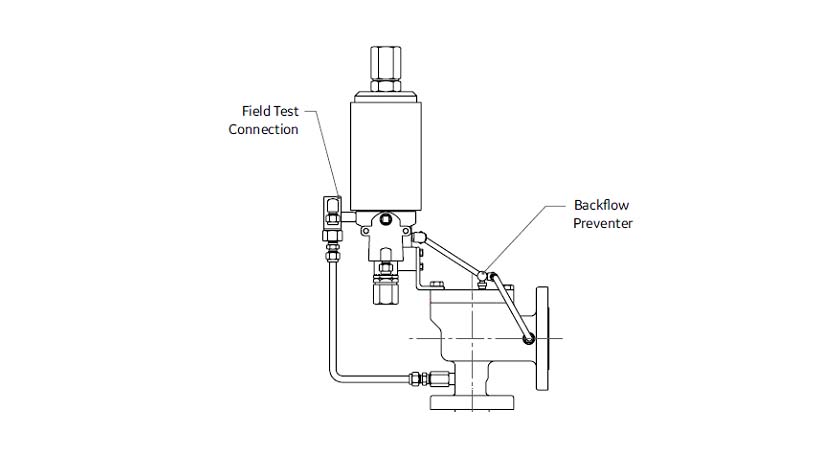

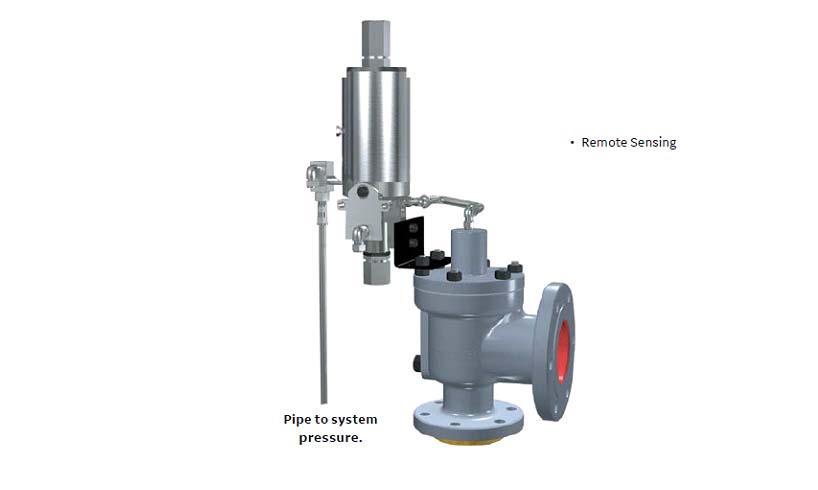

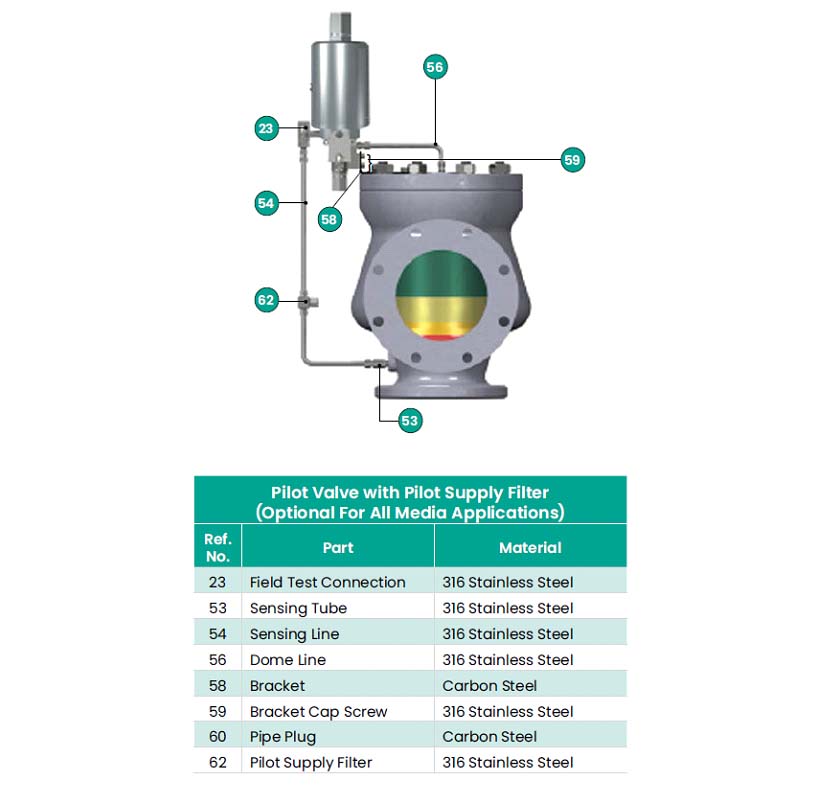

Field Test Connection

A field test connection is standard on all pilot valve types. This allows the stroking of the valve with an auxiliary media, e.g. air or nitrogen. An internal check valve is present in the field test connection isolating the inlet media from the test media and at the same time, allowing the valve to open normally in the event of a system over pressurization during a field test. The test port connection is a .375” (9.53 mm) tube fitting equipped with a bug screen. For all applications on air, water over 140°F (60 °C), or steam service, ASME Section VIII - Division 1 requires each pressure relief valve to have a lifting device such as a field test connection or a means of connecting or applying pressure to the pilot to verify that the moving parts essential to good operation are free to move. (Reference UG 136(a)(3)). The lifting lever or field test connection may be omitted under Code Case 2203. All orders for pressure relief valves without levers or field test connection for steam, air and water over 140°F (60°C) must state specifically that the valves are being purchased per Code Case 2203. The purchaser is responsible for obtaining jurisdictional authorization.

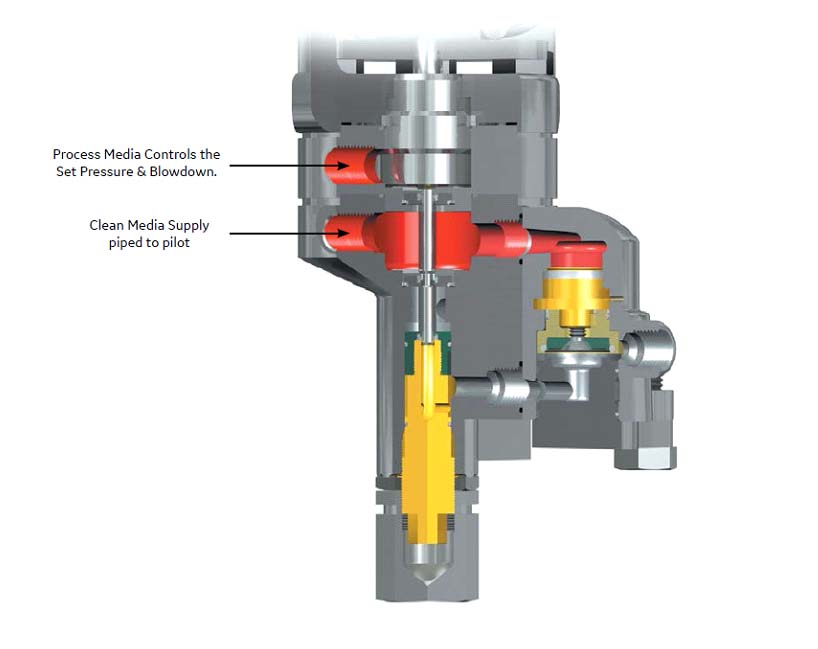

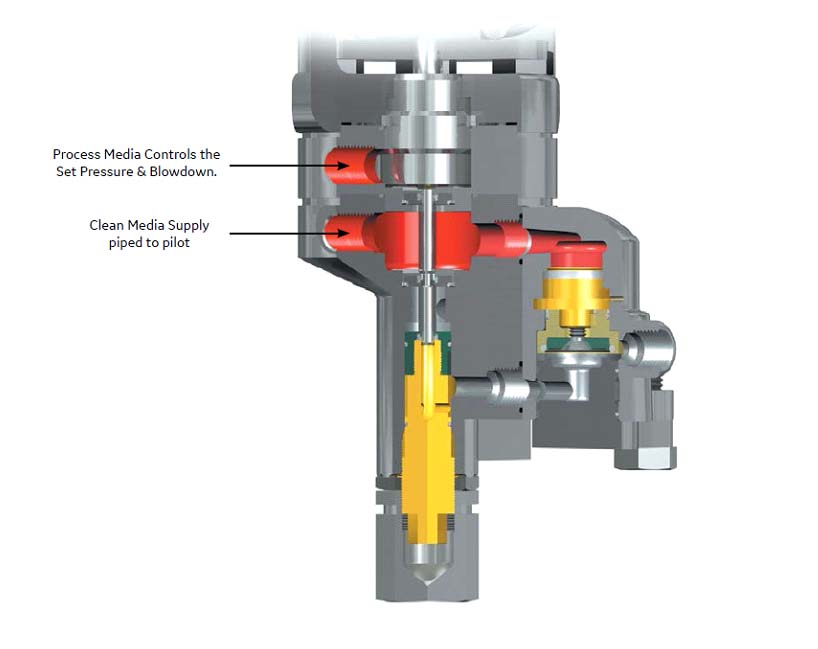

Dirty Service Option

Severe dirty service, precipitation and viscous fluid problems

can be solved using the dirty service option offered on the

2900 series POSRV. A dirty service option can be added to

the standard pilot valve. The kit contains a 316 SS chamber,

an isolation seal and an extended pilot piston. The module

is positioned at the top of the pilot valve body and below

the pilot valve yoke. Crucial valve components such as the

modulator, dome assembly, vent, and inlet seals never come

in contact with the dirty system media. The process media

pressure still controls the set pressure and blowdown of the

POSRV. For applications requiring the main valve to relieve the

Dirty fluid, an alternate clean media supply is piped to the pilot.

The alternate clean media must be set at the same pressure

as the set pressure of the pilot valve, but cannot exceed 3750

Psig (258 .6 barg), which is the design limit of the pilot valve.

If the alternate clean media supply is lost, the main valve will

fail in the open position.